https://dx.doi.org/10.14482/inde.43.01.001.201

Edible Coating Based on Aloe Vera Mucilage to Preserve Whole Slices of Pineapple Fruit

Recubrimiento comestible a base de mucilago de sábila para conservar rodajas enteras de piña

Saúl Dussán-Sarria*

José Igor Hleap-Zapata**

Jesús Hernán Camacho-Tamayo***

Correspondencia: Saúl Dussan Sarria. Universidad Nacional de Colombia, Sede Palmira. Dirección: Carrera 32 n.° 12-00, Vía a Candelaria, Palmira (Colombia). (602) 2868888. sdussan@unal.edu.co

Abstract

This work is aimed at studying the changes in the quality attributes of fresh-cut pineapple fruit due to the application of a coating based of aloe vera. 10 kg of fresh fruit were selected and classified, from which cuts were obtained from whole slices that were previously sanitized and immersed in a 1.5% (w/w) of solution of calcium chloride, citric acid at 1.5% (w/w), and ascorbic acid at 1.5% (w/w), then, the edible coating was applied, which was made from Aloe vera gel to 50% (w/w), glycerol to 1.75% (w/w), polysorbate 20 to 0.01% (w/w), canola vegetable oil to 0.7% (w/w), and distilled water to 47.54%. The pineapple fruit in whole slices, with coating based of aloe vera, packed in vacuum, and stored at 5±1°C and 85±3% RH, presented suitable sensory attributes, pH values and firmness, and microbiological values up to day 15 storage.

Keywords: Ananas comosus, cold storage, fresh-cut, quality attributes.

Resumen

Este trabajo tuvo como objetivo estudiar los cambios en los atributos de calidad de calidad de la piña mínimamente procesada debidos a la aplicación de un recubrimiento a base de aloe vera. Fueron seleccionados y clasificados 10 kg de fruta fresca, de los cuales se obtuvieron rodajas completas, las cuales fueron previamente higienizadas y sumergidas en solución de cloruro de calcio de 1.5 % (p/p), ácido cítrico de 1.5 % (p/p) y ácido ascórbico de 1.5 % (p/p), y luego se les aplicó el recubrimiento comestible, el cual estuvo compuesto de 50 % (p/p) de gel de aloe vera, 1,75 % (p/p) de glicerol 0,01 % (p/p) de polisorbato, 20, 0,7 % (p/p) de aceite vegetal de canola y 47,54 % de agua destilada. Las rodajas enteras de piña recubiertas con Aloe vera, empacados en vacío y almacenadas a 5±1°C y 85±3 % HR, mostraron valores sensoriales, pH, firmeza y valores microbiológicos adecuados al dia I5 de almacenamiento.

Palabras clave: almacenamiento refrigerado, Ananas comosus, atributos de calidad, mínimamente procesado.

Fecha de recepción: 29 de septiembre de 2023

Fecha de aceptación: 31 de agosto de 2024

INTRODUCTION

Pineapple fruit (ananas comosus), after bananas and citrus fruits, is one of the tropical fruits with the highest production in the world. Pineapple fruit is produced in subtropical and tropical regions with a world production of 27'816,403 million tons, and, in Colombia, of 882.633 thousand tons in 2020 [1]. According to Agronet [2], there is a growing trend in world production, with the Honey Gold or MD2 variety being the most appreciated worldwide. The "Honey Gold' pineapple has a cylindrical, symmetrical, and uniform shape, yellow-orange pericarp, yellow, sweet, compact, and fibrous pulp with an average weight of 1,3 to 2,5 kg, with a high content of sugars and ascorbic acid [3].

Pineapple is a tropical non-climacteric fruit, with important nutritional value and sensory quality, however, it has a short shelf life of 5 to 7 days stored at 4 °C due to deterioration caused by its accelerated metabolism induced by minimal processing [4], where the cut fruit is susceptible to alteration of physical, chemical or microbiological stability. If this cut fruit is not treated under the indicated postharvest conditions, it is possible to decrease its shelf life of the products losing its quality and safety [5].

Fresh-cut fruits have increased their market, due to consumer demand [3]. Fresh-cut fruits in different shapes depending on the fruit structure, marketed in plastic packaging and refrigerated are alternatives to preserve the inherent organoleptic and nutritional properties typical of fruits [6].

Lima, De Souza and Fyfe [7] mention that minimal processing operations alter the integrity, safety, quality, and shelf life of the fruit limiting its storage and marketing; furthermore, the selection of adequate packaging that acts as a protective barrier, to minimize water loss and facilitate transport and handling, and storage temperature, are essential to maintain the quality of the fresh-cut vegetable.

The use of edible coatings, which are made from natural materials such as polysaccharides, proteins and lipids, emulsifying additives, surfactants, plasticizers, and antimicrobial agents [8] has increased, becoming a healthy alternative and adding value to the final product. Edible coating is a thin layer that adheres to the fruit completely covering it [9], benefiting physicochemical, sensory, and microbiological properties in vegetables [10]. Aloe vera mucilage, known in Colombia as aloe vera, is being used as a coating for cut vegetables, providing them with an added nutritional value defined by minerals, water, vitamins, enzymes, and carbohydrates beneficial to human health [11].

Aloe vera has been used as a base for edible coatings on table grapes, strawberry, pineapple, kiwi, mango, apple [10]. This research aimed to evaluate the effect of aloe vera-based edible coating applied on fresh-cut "Golden' pineapple on quality parameters maintain in refrigerated storage.

MATERIALS AND METHODS

Location and Raw Material

Ten kg of pineapple (ananas comosus) "Golden' variety obtained from producers in Valle del Cauca were used. The fruits were selected and classified according to size and maturity grade 3 (15 °Brix), according to the color scale for fresh pineapple fruit registered in the NTC 729-1 standard [12]. The whole fruits, after minimal processing, were kept refrigerated at 5°C for 12 h.

Minimal Pineapple Processing

The whole pineapple was subjected to immersion in potable water, and then in a water solution with sodium hypochlorite at 100 ppm and pH 7 for 10 min [13], then rinsed with potable water. The crown, peel, and core were removed from the whole fruit with a stainless-steel die, and, finally, whole slices of 70 mm of diameter and the 12 mm of height were obtained. This type of cut was defined in preliminary trials.

The fruit slices were sanitized in a water and sodium hypochlorite solution at 20 ppm for 2 min [14], and excess moisture was removed in a centrifuge (Kohinoor, A655, Argentina) for 15 s at 1800 rpm. The fruit slices were immersed in a calcium chloride solution with 1.5% (w/w), citric acid 1.5% (w/w), and ascorbic acid 1.5% (w/w) during 3 min, and left to drain for 2 min on absorbent paper [15].

Coating Materials

The coating was made with aloe vera gel and canola vegetable oil purchased in the local market. Food grade glycerol was used as plasticizer purchased from Essential Depot® in the USA, food grade polysorbate 20 as surfactant from Sigma-Aldrich® of Germany and distilled water.

Preparation of the Edible Coating

The edible coating was prepared with the following components: 50% (w/w) aloe vera gel (g aloe vera/100 g solution), glycerol 1,75% (w/w), polysorbate 20 0.01% (w/w), canola vegetable oil 0.7% (w/w), and completed to 100% with distilled water. This solution was heated to 85°C during 5 min and cooled to 25°C, then homogenized at 16.000 rpm for 4 min in an Ultra-Turrax® (ika, Germany). Glycerol previously dissolved in distilled water at 50°C, polysorbate 20, and canola vegetable oil previously dissolved in distilled water at 35°C were added, this solution was stirred for 5 min at 16,000 rpm, and left to cool at 20°C. Then, the fruit pieces were immersed.

Application of the Edible Coating

5,000 g of edible coating solution were prepared. Pineapple in whole slices were immersed in the coating solution (1,28 g per piece of fruit) for 30 seconds and dried at room temperature (approximately 25 °C) for 5 min. Pineapple in whole slices were kept without coating application (control treatment).

150g of fresh-cut pineapple were vacuum packed in low density polyethylene bags of 70 µm caliber, O2 permeability of 39 cm3.m-2.day-1 and CO2 permeability of 107 cm3.m-2.day-1 with each container being the experimental unit. This container was used according to the recommendation made by Dussán-Sarria; Reyes-Calvache and Hleap-Zapata [14]. Quality parameters were evaluated in triplicate during days 0, 3, 6, 6, 9, 9, 12 and 15 of cool storage at 5 ± 1°C and 85 ± 3% RH [16].

Physicochemical Parameters

The pH was determined according to Colombian technical standard NTC 4592 [17], using a SPER SCIENTIFIC 850 digital pH meter (USA). The percentage of titratable acidity (TA) was determined according to NTC 4623 [17] expressed on the basis of citric acid. The soluble solids content in °Brix (SS) was determined according to NTC 4624 [17] using a SPER SCIENTIFIC 300053 (USA) digital refractometer and the maturity index (MI) was determined using equation 1.

Firmness

The EZTEST-S texturometer with a 500 N load cell (Shimadzu Corporation, Japan) and TRAPEZIUM X software version 1.1.3 were used. A 3 mm diameter punch and a deformation rate of 10 mm/s with a maximum depth of 5 mm were used in the penetration test. The load was applied in a direction perpendicular to the surface of the pineapple in whole slices [13]. The values were expressed in Newton (N).

Percentage of Exuded Liquid (Le)

It was calculated as the percentage of the weight of liquid exuded by the pineapple (We) inside the container in relation to the initial weight (Wi) of the pineapple at the beginning of storage, through equation 2.

Color

A colorimeter (Konica Minolta CR410, Japan) with 2° viewing angle and D65 illuminant was used to determine the color of the pineapple slices. The colorimeter was calibrated with the standard white reflector plate (Y=89,5, x=o,3176, y=0,3347) and the value of the coordinates L* indicating brightness, the a* color value indicated the variation from green to red, and b * variation from blue to yellow were measured and the AE (total color difference) was calculated.

To determine the total color difference in each refrigerated storage period, the color values at the beginning of storage were taken as a reference.

Sensory Evaluation

The sensory attributes aroma, flavor, and general appearance of pineapple in whole slices were considered. The panel was conducted with 50 untrained panelists, men and women between the ages of 20 and 60 years old, all from the university community, and a 5-point affective hedonic scale was used to define the degree of satisfaction where: 5 (I like very much), 4 (I like), 3 (I like nor dislike), 2 (I dislike), 1 (I dislike very much) [18]. Results with scores equal to or higher than 3 were considered as product acceptance. The values of the sensory evaluation were the main reference considered to define the shelf life of the food.

Microbiological Analysis

The count of molds and yeasts, expressed in CFU/g (colony forming units per gram) was performed according to ISO 21527-2 [19], using DG18 agar as culture medium. Aerobic mesophilic count in CFU/g was performed according to the AOAC 966.23 [20] method using Palcam agar as culture medium. Total coliforms and fecal coliforms expressed in MPN/g (most probable number per gram) were determined according to the ISO method 4832 [21] using Red Bile Violet lactose agar as culture medium.

Statistical Analysis

Two treatments consisting of coated pineapple in whole slices (CR) and uncoated pineapple in whole slices (Control) were evaluated. A simple completely randomized experimental design was considered, descriptive statistics were performed, via the ANOVA (analysis of variance) and comparison of means and Duncan's multiple range test (p<0,05). The statistical software SAS® version 9.1 (USA) was used.

RESULTS AND DISCUSSION

Physicochemical Parameters

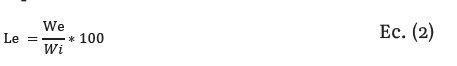

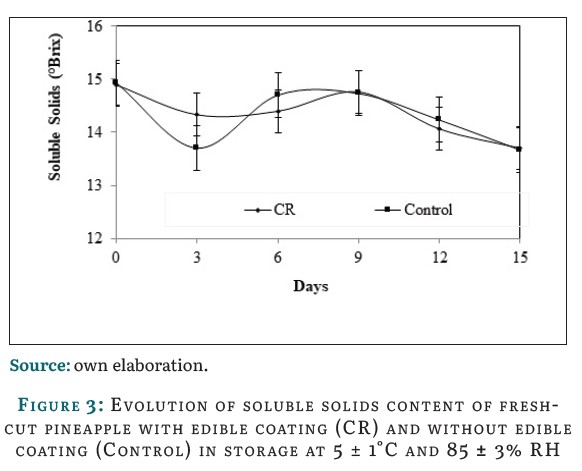

The pH values remained constant during the refrigerated storage period in all treatments and exhibited significant statistical differences (p<0.05) between the coated pineapple and the control pineapple (Figure 1), being that, on day 15 of storage, the pH values were 3.85 and 4.01, respectively. The variation of one decimal in the pH scale represents a significant concentration of hydrogenions (H+) in a solution because it is a logarithmic scale measurement. The pH values below 4.5 provide stability to the fresh-cut pineapple, from the point of view of safety [22]. Similar pH values were obtained by Mantilla et al. [4]

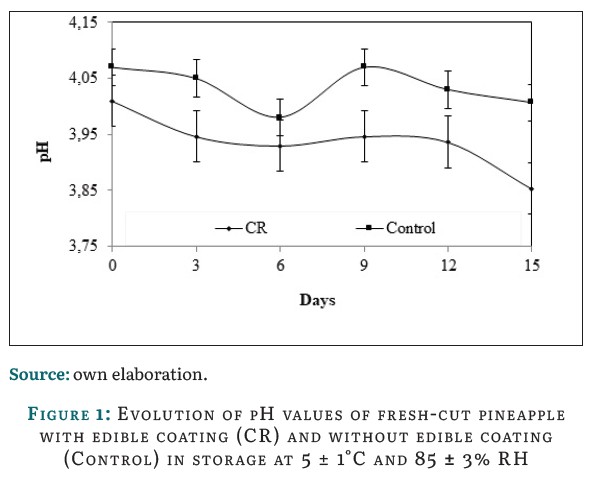

The AT did not present significant statistical differences (p<0.05) between the coated pineapple and the control pineapple (Figure 2) at the end of storage (day 15), considering both treatments, TA values are around 0.32% ± 0.1, values similar to those found by Treviño-Garza et al. [3]. Normally, pineapple during refrigerated storage tends to decrease its organic acid and sugar contents due to the senescence process [23].

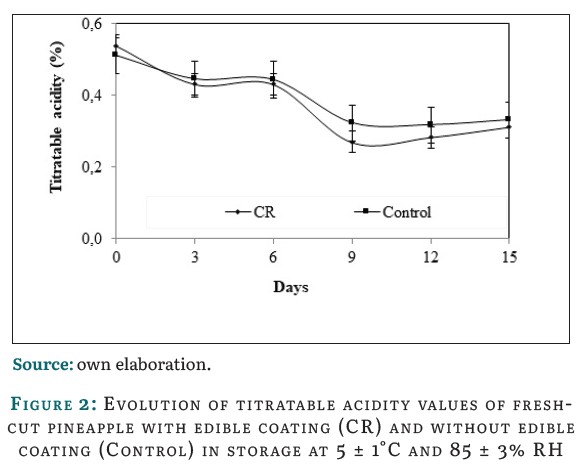

The soluble solids content of CR and control pineapple cuts maintained constant and statistically equal values during refrigerated storage (p<0.05) (Figure 3). On day 15 of storage, the control and CR pineapple presented equal soluble solids content values of 13.67 ± 0.02 Brix.

The edible coating added to the vacuum packaging affected the pH values and had no effect on the soluble solids and the titratable acidity values of the fresh-cut pineapple. The aforementioned confirms that, normally, in non-climacteric fruits such as pineapple, biochemical changes derived from the ripening process do not occur with little incidence on the fruits [16]. Similar results caused by the modified atmosphere were also reported by Dussán-Sarria; Reyes-Calvache and Hleap-Zapata and Pan, Zhu and Li [14]. The incidence of the aloe vera coating in the lower pH values found compared to the control pineapple slices is highlighted. The pH is undoubtedly, together with water activity, the two main stability factors of a food [21].

Percentage of Exuded Liquid

To the end of storage, despite the fact that the loss of exuded liquid of the CR pineapple was lower than that of the Control pineapple, there was no statistical difference (p<0,05) between the values of liquid accumulated up to day 15 of storage, being 8,53 ± 0,32 % and 9,29 ± 0,34 %, respectively. The edible coating used on the cut fruit, in synergy with vacuum packaging, helped to reduce this liquid loss. Benitez et al. [23] also found a high loss of exuded liquid in fresh-cut pineapple coated with chitosan, packaged in modified atmosphere, and refrigerated.

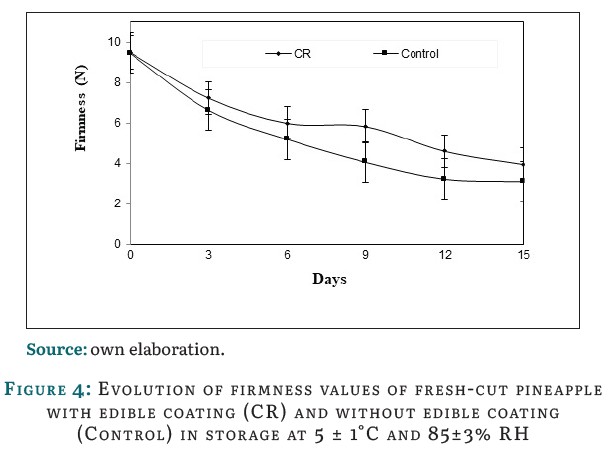

Firmness

Figure 4 shows the decreasing behavior of fruit firmness values during the refrigerated storage period. The CR pineapple presented on day 15 of storage, a higher firmness value than the control pineapple (p<0,05), 3.97 ± 0,54 N and 3,12 ± 0,36 N, respectively.

The higher firmness value in the coated pineapple during refrigerated storage is due to the fact that the aloe vera gel has textural properties, maintaining the firmness of the fruit, and, at the same time, creating a physical barrier to gases and humidity of the medium preventing the softening of the tissues, which slows ripening and senescence [23]. Likewise, this slowing of the ripening metabolism created by the edible coating prevents the action of enzymes such as polygalacturonase, ß-galactosidase, and pectinmethyl esterase responsible for the softening of plant tissues [16], as it also had incidence in the higher values of firmness, the previous application of calcium chloride to the fruit pieces.

According to Djioua et al. [13], the softening of vegetal tissues is one of the principal problems than limiting the shelf life of fresh-cut fruits, and firmness is a key factor influencing consumer acceptability.

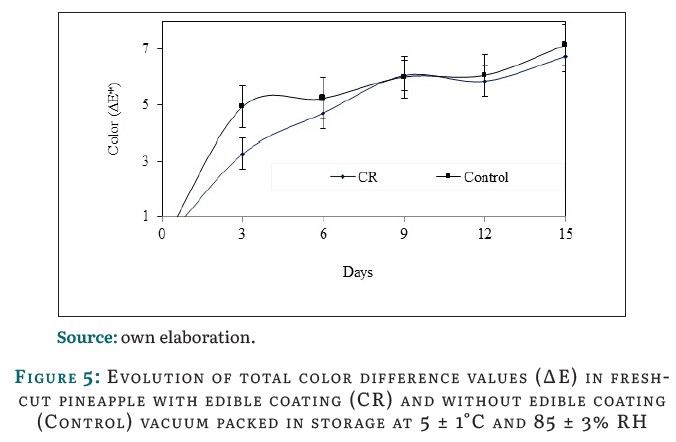

Color

Figure 5 shows the behavior of the values of the total color difference (ΔE) for the two treatments during storage, not observing a significant statistical difference of ΔE between the two treatments (p<0,05). On day 15 of refrigerated storage, CR pineapple and control pineapple exhibited values of 6.73 ± 0.3 and 7.13 ± 0.4, respectively, considering as reference the color at the beginning of storage, i.e., on day 0. The application of organic acids as antioxidants in control and CR pineapple, and vacuum storage slowed down the oxidative processes of phenolic compounds that cause fruit browning [13]. Similarly, the loss of brightness of cut pineapple, indicating greater total color difference ΔE, may be indicative of better consumer acceptance because it is associated with better flavor and succulence [4].

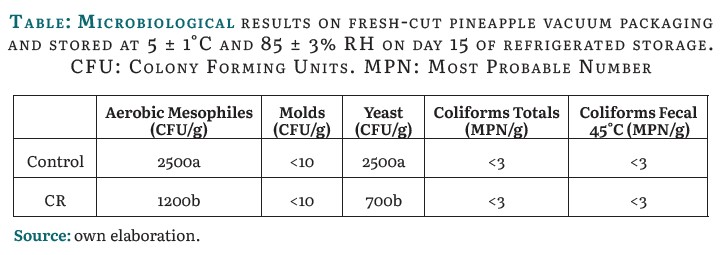

Microbiological Evaluation

The results of microbiological evaluation of pineapple in whole slices on day 15 of refrigerated storage are shown in Table. Pineapple with edible coating presented lower values in aerobic mesophilic and yeast counts compared to pineapple without edible coating (p<0.05). The other microbiological analyses showed the same values with no significant statistical difference.

These results suggest that the edible coating has antimicrobial activity due to some components present in aloe vera such as anthraquinones, saponins, and acemannans; also probably due to the microbial inhibitory effect of the organic acids used as antioxidants, i.e., by the application of citric acid and ascorbic acid [24].

All values of microorganism counts were within the tolerable ranges for food safety for human consumption according to the Colombian Standard Resolution 3929 [25], suggesting that good manufacturing practices were effectively followed.

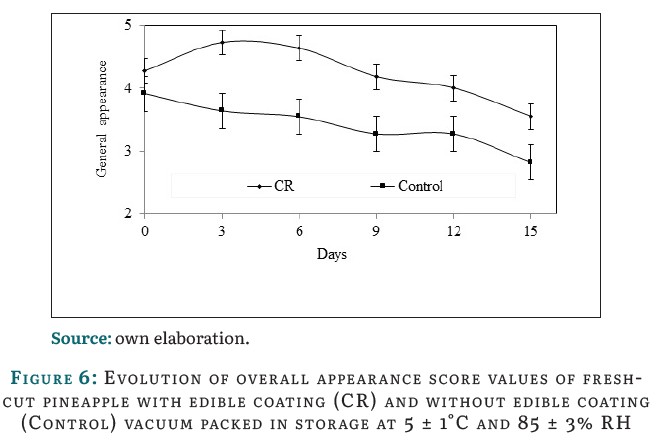

Sensory Evaluation

The sensory attributes of characteristic aroma and characteristic flavor in the control pineapple presented sensory scores below 3 from day 9 of storage. The CR pineapple on the day 15 of storage presented sensory notes of flavor and aroma equal to 3, and the general appearance was positive with a stately note of 4 on day 15 (Figure 6).

The sensory appreciation of fresh-cut pineapple based on the coloration of the product is subjective, as some consumers prefer to consume pineapple with a dark yellow color because they associate it with greater sweetness. Quintero et al. [26] state that an untrained panelist makes a spontaneous judgment of what he/she feels towards a finished product, expressing the perceived quality and subsequently its intensity.

According to Restrepo-Fernández [27], edible coatings based on aloe vera decrease fruit deterioration, enzymatic activity, and respiration, avoiding unpleasant flavors and aromas. Considering the evaluated sensory attributes, the results limit the quality of cut pineapple in whole slices in general for consumption up to day 15.

CONCLUSIONS

The edible coating based in aloe vera presented a positive impact on pH values, firmness values, sensory, and microbiological attributes in fresh-cut "Golden' pineapples. The fresh-cut pineapple in whole slices, coated with an aloe vera-based solution and vacuum packed, retains its quality attributes up to day 15 of storage at 5 ± 1°C and 85 ± 3% RH.

* Grupo de Investigación en Manejo y Agroindustrialización de Productos de Origen Biológico, Universidad Nacional de Colombia Sede Palmira (Colombia). Ingeniero agrícola, Ph.D. en Ingeniería Agrícola. Profesor Titular del Programa de Ingeniería Agroindustrial. Orcid-ID: https://orcid.org/0000-0001-9297-0781. sdussan@unal.edu.co

** Grupo de Investigación en Manejo y Agroindustrialización de Productos de Origen Biológico, Universidad Nacional de Colombia Sede Palmira (Colombia). Ingeniero pesquero, Ph.D. en Ingeniería de Alimentos. Profesor asociado del Programa de Ingeniería Agroindustrial. Orcid-ID: https://orcid.org/0000-0001-9692-5443. jihleapz@unal.edu.co

*** Facultad de Ingeniería, Departamento de Ingeniería Civil y Agrícola, Universidad Nacional de Colombia, Sede Bogotá. Bogotá, Colombia. Ingeniero Agrícola, Ph.D. en Ciencias Agrarias. Profesor asociado del Programa de Ingeniería Agrícola. Orcid-ID: https://orcid.org/0000-0002-7066-369X. jhcamachot@unal.edu.co

REFERENCES

[1] FAOSTAT. Datos sobre alimentación y agricultura. Organización de la Naciones Unidas para la Alimentación y la Agricultura - FAO, 2022. https://www.fao.org/faostat/es/#home

[2] AGRONET. Red de Información y Comunicación del Sector Agropecuario Colombiano. Ministerio de Agricultura y Desarrollo Rural (2022). https://agronet.gov.co/Paginas/inicio.aspx

[3] Treviño-Garza, M. Z. et al. Layer-by-Layer Edible Coatings Based on Mucilages, Pullulan and Chitosan and Its Effect on Quality and Preservation Of Fresh-Cut Pineapple (Ananas comosus), Postharvest Biology and Technology, 128: 63-75, 2017. https://doi.org/10.1016/j.postharvbio.2017.01.007.

[4] Mantilla, N. et al. Multilayered Antimicrobial Edible Coating and Its Effect on Quality and Shelf-Life of Fresh-Cut Pineapple (Ananas comosus). LWT-FoodScience and Technology, 51(1): 37-43, 2013. https://doi.org/10.1016/j.lwt.2012.10.010

[5] Basharat, Y.; Abhaya, K. S. Impact of Honey Treatments and Soy Protein Isolate-based Coating on Fresh-cut Pineapple During Storage at 4°C. Food Packaging and Shelf Life, 21: 1-9, 2019. https://doi.org/10.1016/j.fpsl.2019.100361

[6] Turazzi, F.C. et al. Evaluation of Volatile Profiles Obtained for Minimally-Processed Pineapple Fruit Samples During Storage by Headspace-Solid Phase Nicroextraction Gas Chromatography-Mass Spectrometr. Food Science and Technology, 37(4): 663-672, 2017. https://doi.org/10.1590/1678-457X.29316

[7] Lima, P. C. C.; De Souza, B. S.; Fyfe, S. Influence of storage temperature and different packaging on the physicochemical quality of fresh-cut 'Perola' pineapple. Idesia, 37(2): 13-19, 2019. http://dx.doi.org/10.4067/S0718-34292019000200013.

[8] Falguera, V. et al. Edible Films and Coatings: Structures, Active Functions and Trends in Their Use. Trends in Food Science & Technology, 22(6): 292-303, 2011. https://doi.org/10.1016/j.tifs.2011.02.004.

[9] Vázquez-Briones, M. C. et al. Recubrimientos de Frutas con Biopelículas, Temas Selectos Ing. Alimentos, 7(2), 5-14 (2013).

[10] De Ancos, B., D. et al. Uso de Películas/Recubrimientos Comestibles en los Productos de IV y V Gama. Revista Iberoamericana de Tecnología Postcosecha, 16(1): 8-17, 2015. http:// www.redalyc.org/articulo.oa?id=81339864002

[11] Velázquez-Moreira, A.; Guerrero-Beltran, J. A. Algunas Investigaciones Recientes en Recubrimientos Comestibles Aplicados en Alimentos. Temas Selectos Ingeniería de Alimentos. (México), 8(2): 5-12, 2014.

[12] ICONTEC - Instituto Colombiano de Normas Técnicas y Certificación. Norma Técnica Colombiana NTC 729-1. Frutas frescas. piña. especificaciones, Colombia: 10p, 1996. https://www.icontec.org/

[13] Djioua, T. et al. Improving The Storage of Minimally Processed Mangoes (Mangifera indica L.) by Hot Water Treatments. Postharvest Biology and Technology, 52(2): 221-226, 2009. https://doi.org/10.1016/j.postharvbio.2008.10.006

[14] Dussán-Sarria, S.; Reyes-Calvache, P. M.; Hleap-Zapata, J. I. Efecto de un Recubrimiento Comestible y Diferentes Tipos de Empaque en los Atributos Fisicoquímicos y Sensoriales de Piña "Manzana' Mínimamente Procesada. Información tecnológica, 25(5): 41-46, 2014. http://dx.doi.org/10.4067/S0718-07642014000500007

[15] Rincón-Pérez, A.; Martínez-Quintero, E., Funciones del Calcio en la Calidad Poscosecha de Frutas y Hortalizas: una revisión. Revista de la Asociación Colombiana de Ciencia y Tecnología de Alimentos (Alimentos Hoy), 24(34): 13-25, 2015. https://alimentoshoy.acta.org.co/index.php/hoy/article/view/301

[16] Kader, A. A. Postharvest Technology of Horticultural Crops, United States: University of California Agriculture and Natural Resources, 2002. 535p.

[17] ICONTEC - Instituto Colombiano de Normas Técnicas y Certificación. Norma Técnica Colombiana NTC 4592, NTC 4623, NTC 4624. Productos de frutas y verduras, Colombia, 1999. https://www.icontec.org/

[18] Lim, J. Hedonic scaling: A review of Methods and Theory. Food Quality and Preference, 22(8): 733-747. 2011.

[19] ISO - International Organization for Standardization. ISO 21527-2. Microbiology of food and animal feeding stuffs-Horizontal method for the enumeration of yeasts and moulds-Part 2: Colony count technique in products with water activity less than or equal to 0,95, 9p, 2008. https://www.iso.org/obp/ui/#iso:std:iso:21527:-2:ed-1:v1:en

[20] AOAC - Association of Officiating Analytical Chemists. Official method of Analysis. Method 966.23. 21st Edition, Washington DC. (2019). https://www.aoac.org/

[21] ISO - International Organization for Standardization. ISO 4832. Microbiology of food and animal feeding stuffs-Horizontal method for the enumeration of coliforms. Colony-count technique, 6p, 2006. https://www.iso.org/obp/ui/#iso:std:iso:4832:ed-3:v1:en

[22] Azeredo, H. M. C. Fundamentos de estabilidade de alimentos. 1a. Ed. Fortaleza, Brasil: Embrapa, 195p (2004)

[23] Benítez, S. et al. Combined Effect of a Low Permeable Film and Edible Coatings or Calcium Dips on the Quality of Fresh-Cut Pineapple. Journal of Food Process Engineering, 37(2): 91-99, 2014. https://doi.org/10.1111/jfpe.12063

[24] Pérez, A. F.; Aristizábal, I. D.; Restrepo, J. I. Conservación de Mango Tommy Atkins Mínimamente Procesado Mediante la Aplicación de un Recubrimiento de Aloe Vera (Aloe Barbandensis miller). Vitae, 23(1): 65-77, 2016. https://doi.org/10.17533/udea.vitae.v23n1a07.

[25] INVIMA - Instituto Nacional de Vigilancia de Medicamentos y Alimentos. Ministerio de Protección Social. Colombia. Res. 3929, 29, 2013. https://www.invima.gov.co/

[26] Quintero, C. et al. Training of Judges for Estimating the Color of the Instant Oatmeal Strawberry Sabor of Rice and Cream Sabor Arequipe. Alimentech Ciencia y Tecnología Alimentaria, 12(1): 93-100, 2014.

[27] Restrepo Fernández, Jorge Iván. Conservación de fresa (Fragaria x ananassa Duch cv. Camarosa) mediante la aplicación de revestimientos comestibles de gel mucilaginoso de penca de sábila (Aloe barbadensis Miller) 2009.